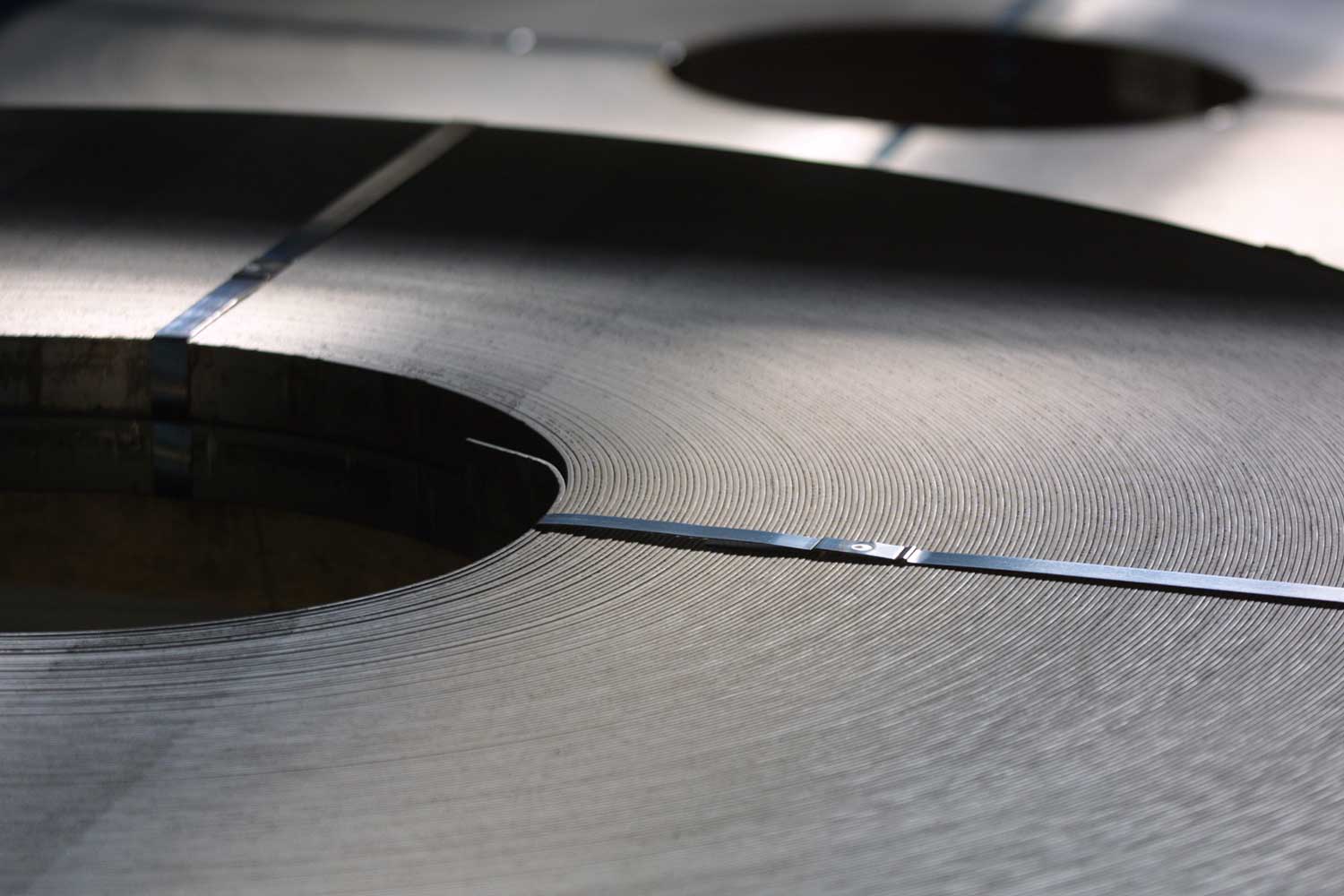

Coils Division

Non alloyed steel products for structural uses

(EN 10025 1-2-5 / 3-4 upon request)

Delivered

PICKLED AND OILED and BLACK-DRY

These steels are widely used in the field of mechanical constructions (from light to heavy structural work) and are irreplaceable in numerous applications linked with civil building (public works) and urban decoration.

Their vast availability, in both formats and quality, enables the designer to make a sure choice of the material best suited to the intended use.

For these reasons this is certainly the most important category of construction steels.

They are generally installed without heat treatment, that is in their untreated rolled state, or at most after simple normalisation.

Deliverable grades of steel

S185

S235 / S275 / S355 – Grades: JR / JO / J2 / K2 bearing the CE mark and DOP S355JOW / S355JOWP

[Suitability for bending (C) or normalization (+N) can be requested]

Hot rolled steel products with a high yield quality for cold forming

(EN 10149 1-2-3)

Delivered

PICKLED AND OILED and BLACK-DRY

High yield quality steels, known also as micro-alloy or high strength steels, have been specially studied and developed for those sectors of application which require:

– high mechanical strength and toughness (resilience at low temperatures)

– excellent cold deformability (bending, profiling, drawing)

– excellent weldability.

These steels are therefore particularly indicated for making all structures/elements that require, besides good workability, a significant reduction of their own weight while maintaining their basic strength properties unchanged.

Their regularity of behaviour in moulding also makes them suitable for all mass production work.

Deliverable grades of steel

S315MC / S355MC / S420MC

S460MC / S500MC / S550MC / S600MC / S650MC / S700MC

S260NC / S315NC / S355NC / S420NC / QSTE380TM

Hot rolled steel products with a low carbon content for cold forming

(EN 10111)

Delivered

PICKLED AND OILED and BLACK-DRY

These are hot rolled steels, mostly intended for drawing and cold forming. They are supplied with a pickled and oiled surface, although there are also applications which require an untreated surface (black-dry).

Deliverable grades of steel

DD11 – DD12 – DD13 – DD14

Non alloy steel products with surface in relief

(tear-drop and chequered sheets) (EN 10025)

Delivered

BLACK-DRY

These rolled steel products are widely used in making many construction components in the field of light structural work and urban decoration.

Their name is closely linked with the particular geometrical conformation of the surface pattern (on only one side), which may present a chequered or buckle effect.

Thanks to their non-slip function/capacity, these sheets are used especially for safety purposes.

They are therefore generally used for the treadable surface of walkways, stairs, lifting platforms, footboards, inclined surfaces, loading ramps, manhole covers, etc.

They are also widely used for the surfaces of weighbridges.

Deliverable grades of steel

S235 / S275 / S355 – Grades: JR / JO / J2

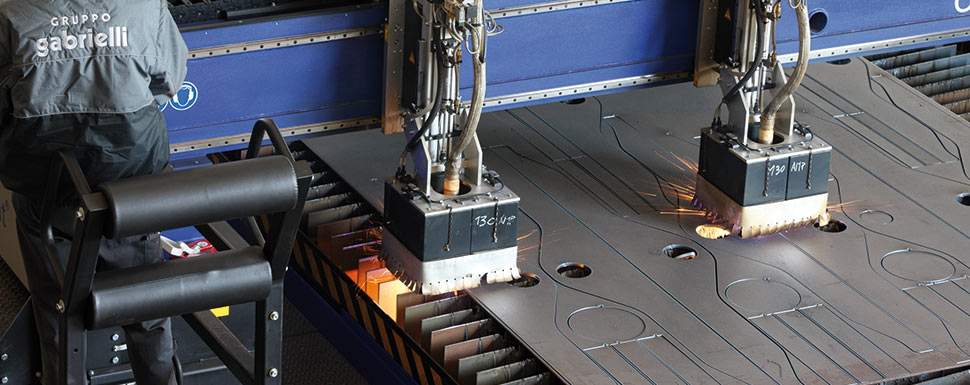

Non alloy steel products suitable for LASER cutting

(LASERALF)

Delivered

PICKLED AND OILED and BLACK-DRY

LASERALF steels are hot rolled steel products with a low carbon content, characterised by special suitability for laser cutting.

They are excellent for use in automatic production processes, due to their constant strength (mechanical homogeneity), the strict control of their chemical analysis and close dimensional tolerances, as well as excellent weldability.

Their good flatness after cutting and the low residual internal tensions enable LASERALF material to be used in producing parts that require minimum deformability (or none at all) and the absence of burs.

LASERALF is the brand name with which Gabrielli S.p.A. sells sheets suitable for laser cutting.

Deliverable grades of steel

LASERALF 240N (Superior qualities upon request)

Pressure vessel steels

(EN 10028 1-2-3)

Delivered

BLACK-DRY

These are hot rolled steels which are widely used in the manufacture of pressure vessels .

They have specific characteristics for high temperatures, are of fine and normalized grain and are suitable for welding.

They are therefore especially suitable for manufacturing gas and liquid tanks , heat exchangers, for the chemical, petrochemical and petroleum industry, for pressure vessels and for applications the boiler manufacturing industry.

Deliverable grades of steel

P235GH, P265GH, P295GH, P355GH, P275NH, P355NH, P460NH

Steels for the Automotive Industry

according to VDA 239-100

State at delivery

PICKLED AND OILED and BLACK-DRY

These are hot rolled steels, mostly intended for drawing and cold forming.

They are supplied with a pickled and oiled surface, although there are also

applications which require an untreated surface (black-dry).

Deliverable grades of steel

DD11 – DD12 – DD13 – DD14

Non-alloy steels for quenching and tempering

(EN ISO 683-1)

State at delivery

PICKLED AND OILED and BLACK-DRY

They are intended to be heat treated for tempering followed by T-quenching between 540°C

and 680°C depending on the steel and use. They have medium-high carbon concentration

required for a good compromise of resistance and toughness. These steels are generally

intended for the manufacture of mechanical components subjected to high static and

dynamic loads: shafts, axle shafts, rods, connecting parts, columns, presses.

Deliverable grades of steel

C25 – C30 – C35 – C40 – C45 – C50 – C55 – C60

Also available for delivery annealed – globular annealed – normalized